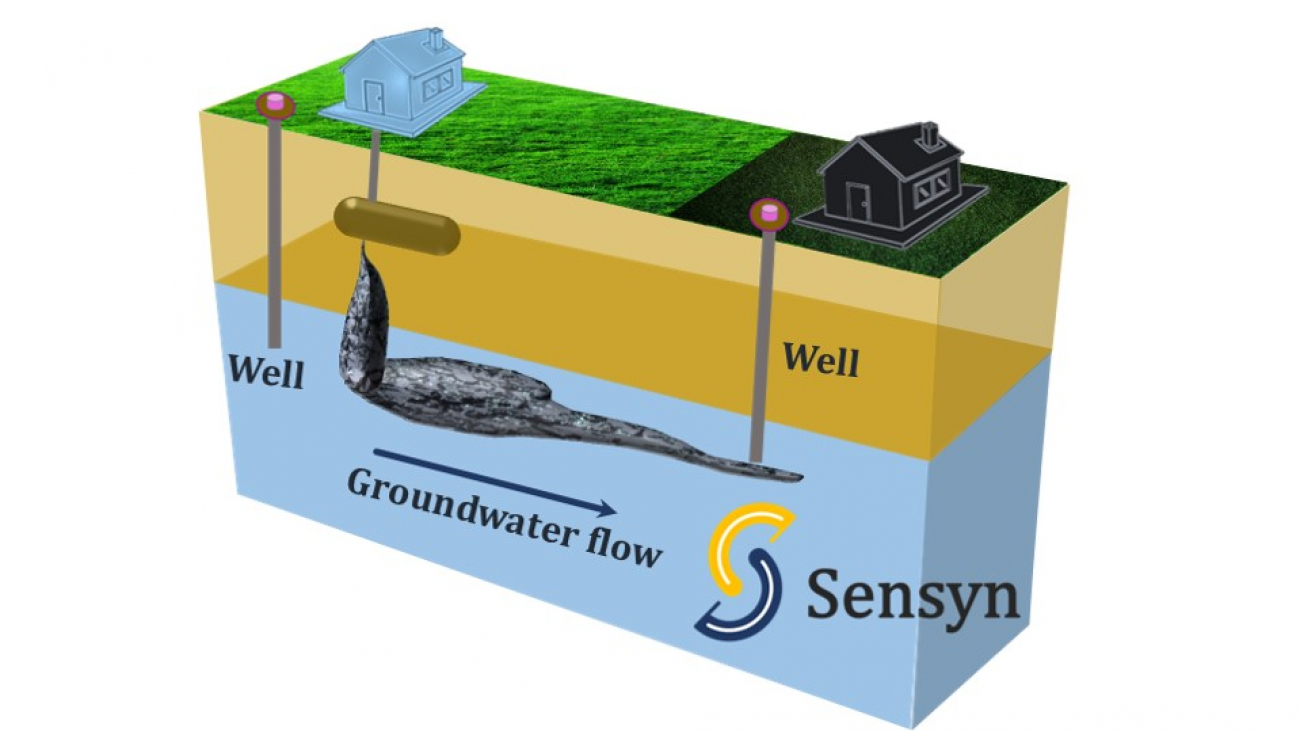

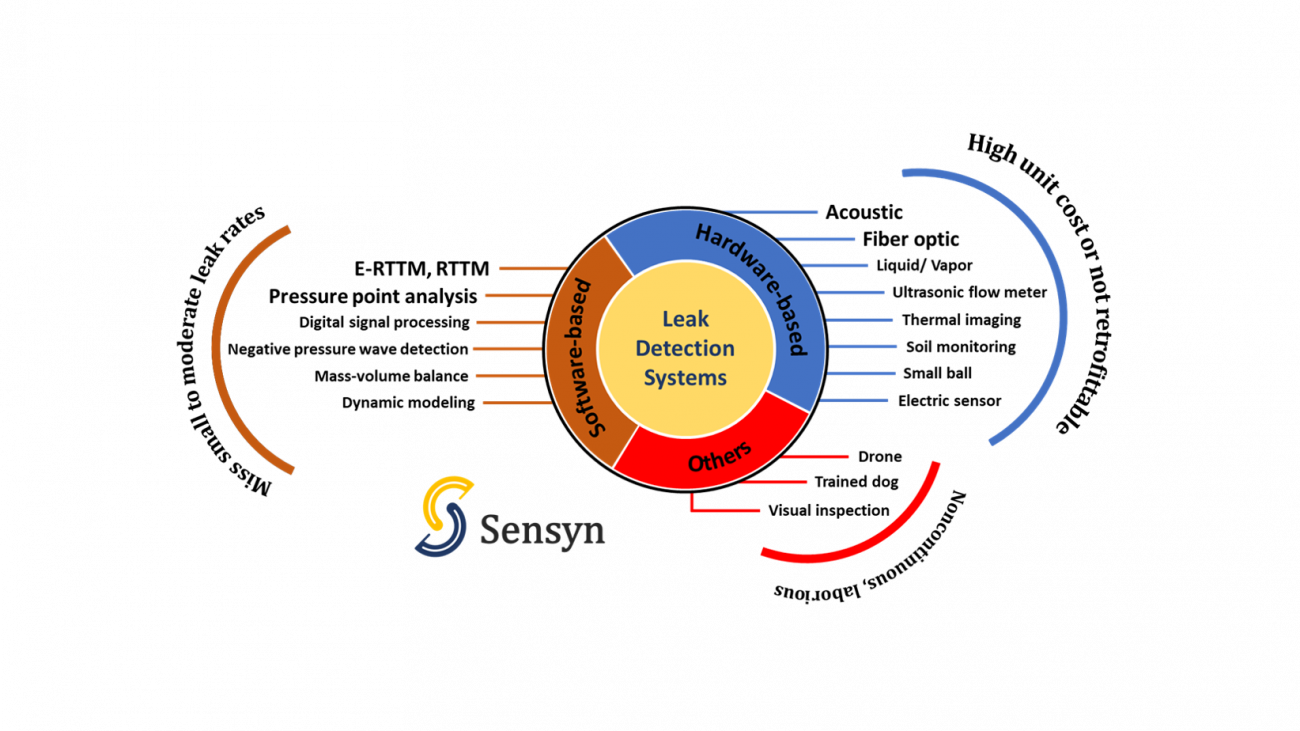

Hydrocarbon spills from oil industries and transporting facilities are a major concern from an environmental and cost perspective. With the increasing demand for fossil fuels and the aging of existing facilities, the risk of oil pollution in the marine, aquifer, and soil is increasing. Damage to tankers and underwater facilities often results in large spills. The dominant approach to assessing these spills is to use satellite-based synthetic aperture radar (SAR) imaging combined with aerial surveillance. However, these methods may not detect small spills or perform poorly when the sea is rough. Also, they are prone to generating false positive signals in very calm conditions. Look-alike slicks from wind shadows, populated algae, and biogenic films can also lead to deterioration in their performance. Their other major drawback is the reliance on satellite location, which limits the use of real-time applications.

Non-accidental hydrocarbon discharges, which are smaller in size but contribute more to the overall marine pollution levels, require more sensitive and rapid detection systems. Spills caused by leaks from ship equipment, de-ballasting, and cleaning are the most common causes of this type of spill. Unfortunately, the most of in-situ approaches are not rapid, economical, or accurate enough to improve decision-making and minimize the spill impacts.