We are delighted to announce that Sensyn Inc. has been accepted into the prestigious Kickstart Program of Foresight Canada!

This significant achievement showcases the dedication, ingenuity, and hard work of our exceptional team. Joining the ranks of the Kickstart Program grants us access to invaluable resources, mentorship, and funding opportunities that will propel our company to new heights.

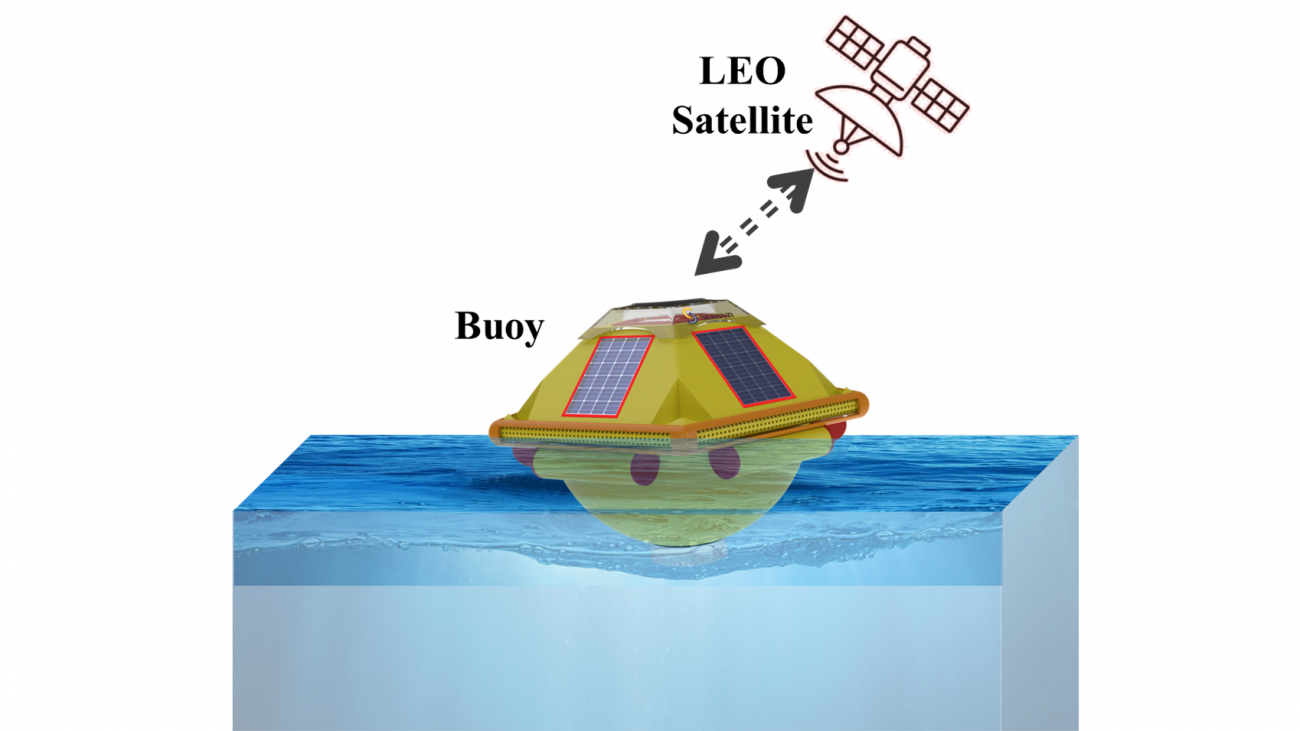

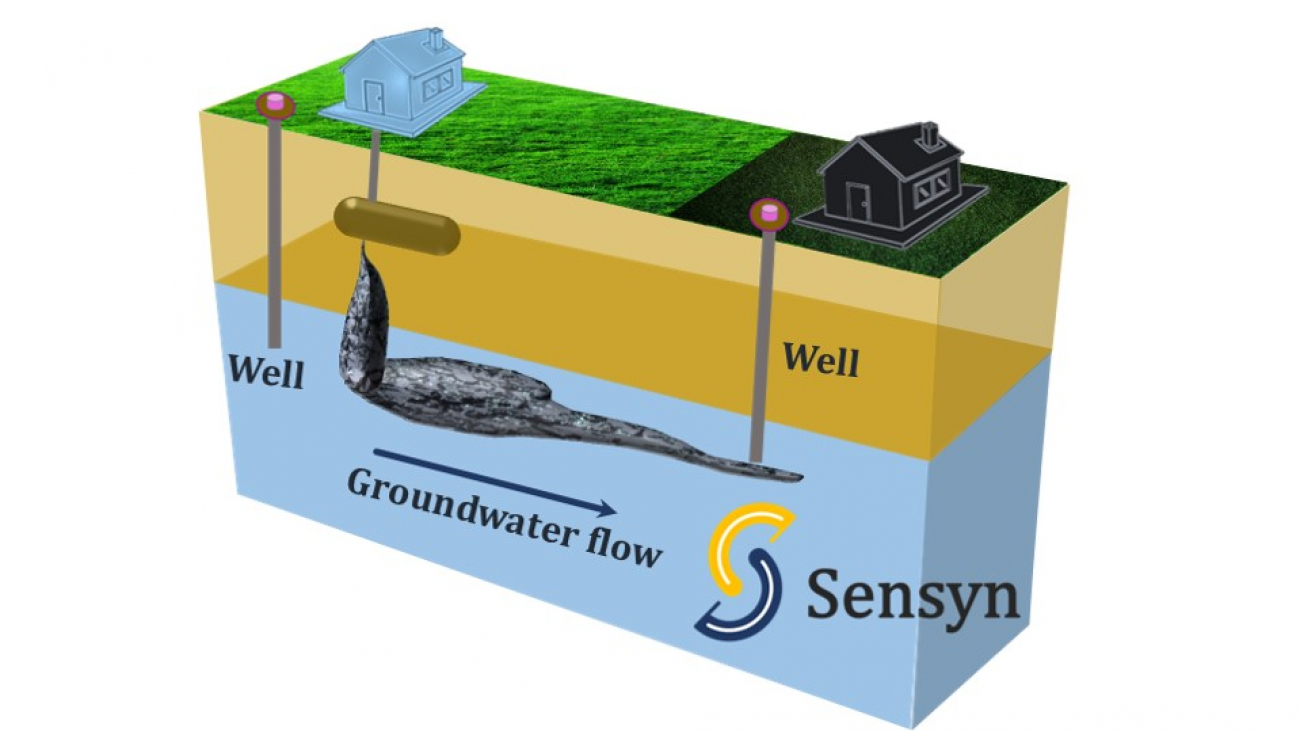

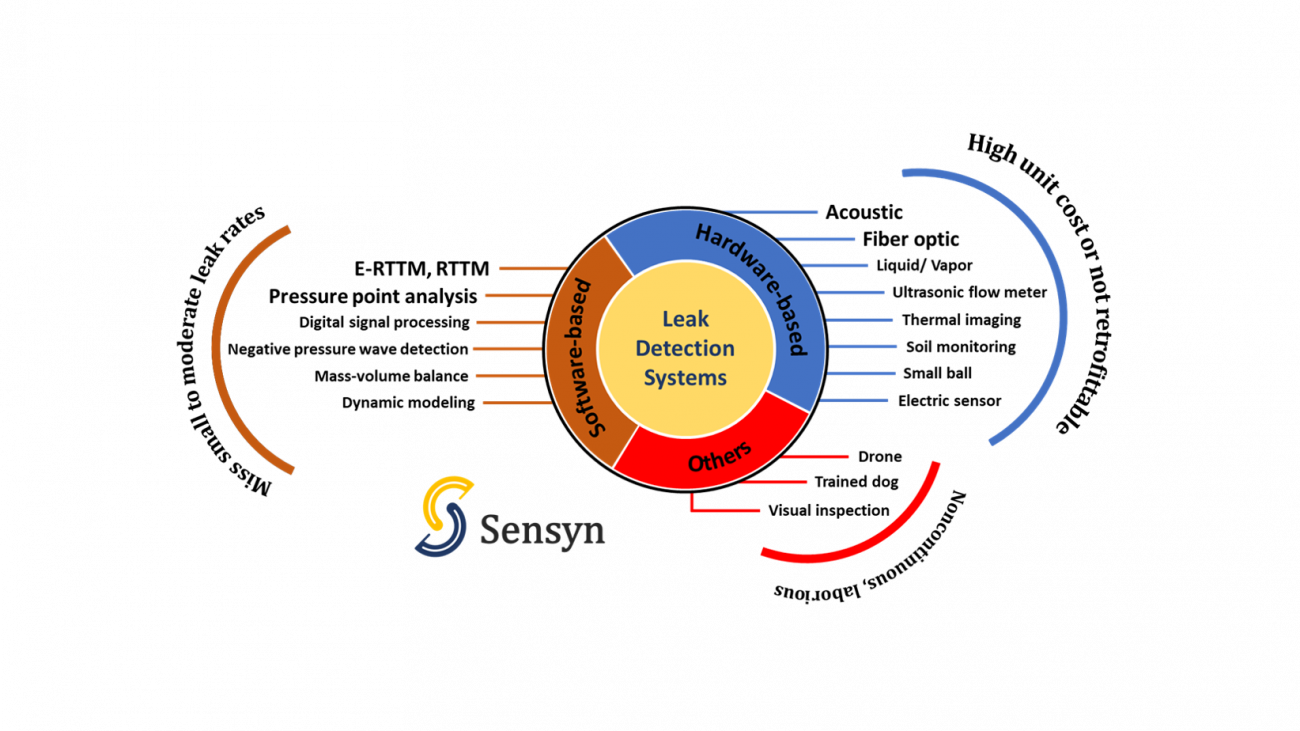

Our acceptance into Foresight Canada’s Kickstart Program serves as a powerful validation of our vision and technological advancements. It reinforces our commitment to transforming the industry and underscores the potential impact of our innovative leak detection solutions.

Collaborating closely with the esteemed Foresight Canada team will enable us to leverage their expertise, tap into their vast network, and accelerate our growth trajectory. We are excited to embark on this journey together, pushing boundaries and achieving remarkable milestones.

We extend our sincere gratitude to all those who have supported us along this remarkable journey. Our dedicated team, visionary mentors, advisors, and strategic partners have played an instrumental role in shaping Sensyn’s success.

This accomplishment fuels our passion and drives us to continuously refine our technology, exceed customer expectations, and contribute to a more sustainable future. We remain steadfast in our commitment to revolutionizing the field of leak detection and making a positive impact on pipelines and facilities worldwide.

Stay tuned for further updates as we embark on this exciting chapter in our company’s evolution with Foresight Canada. Together, we are reshaping the landscape of leak detection and pioneering advancements that will redefine industry standards.