Oil spills are a serious threat to the marine environment, and Canada’s extensive coastline makes it particularly vulnerable to such incidents. These spills can have long-lasting consequences, including damage to ecosystems, marine life, and human health. Therefore, it is crucial to have effective technologies to monitor oil spills and take prompt action to mitigate their effects.

Here are some of the available technologies for monitoring oil spills in Canada’s water:

- Satellite Imagery: Satellite imagery is one of the most effective ways to detect oil spills in the ocean. This technology uses high-resolution images to identify oil slicks and other signs of an oil spill. However, satellite imagery is expensive and may not provide real-time information.

- Aerial Surveys: Aerial surveys are another way to detect oil spills in the ocean. This technology involves flying over the affected area to identify signs of an oil spill. However, aerial surveys are weather-dependent and expensive to conduct.

- Remote Sensing: Remote sensing uses a combination of satellite imagery and aerial surveys to identify oil spills. This technology can provide real-time information about the location and size of the spill. However, it is also expensive and may not be as effective in identifying smaller spills.

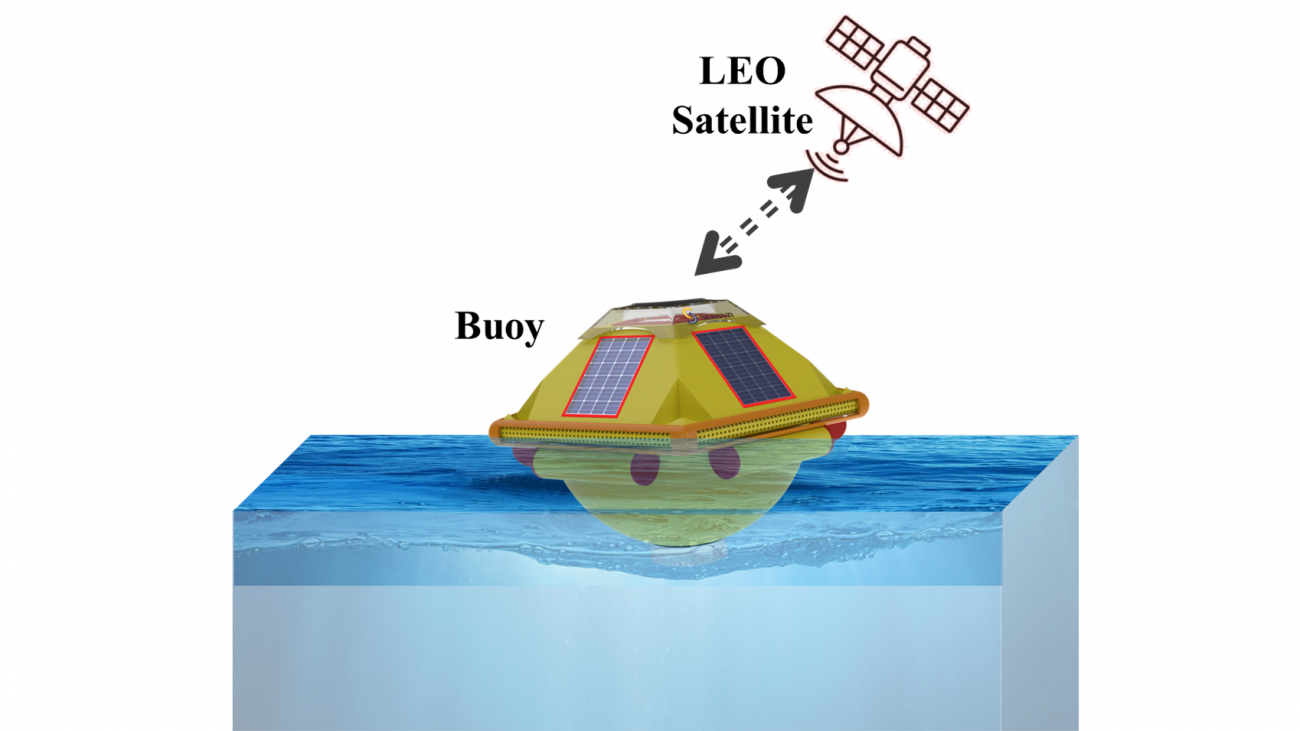

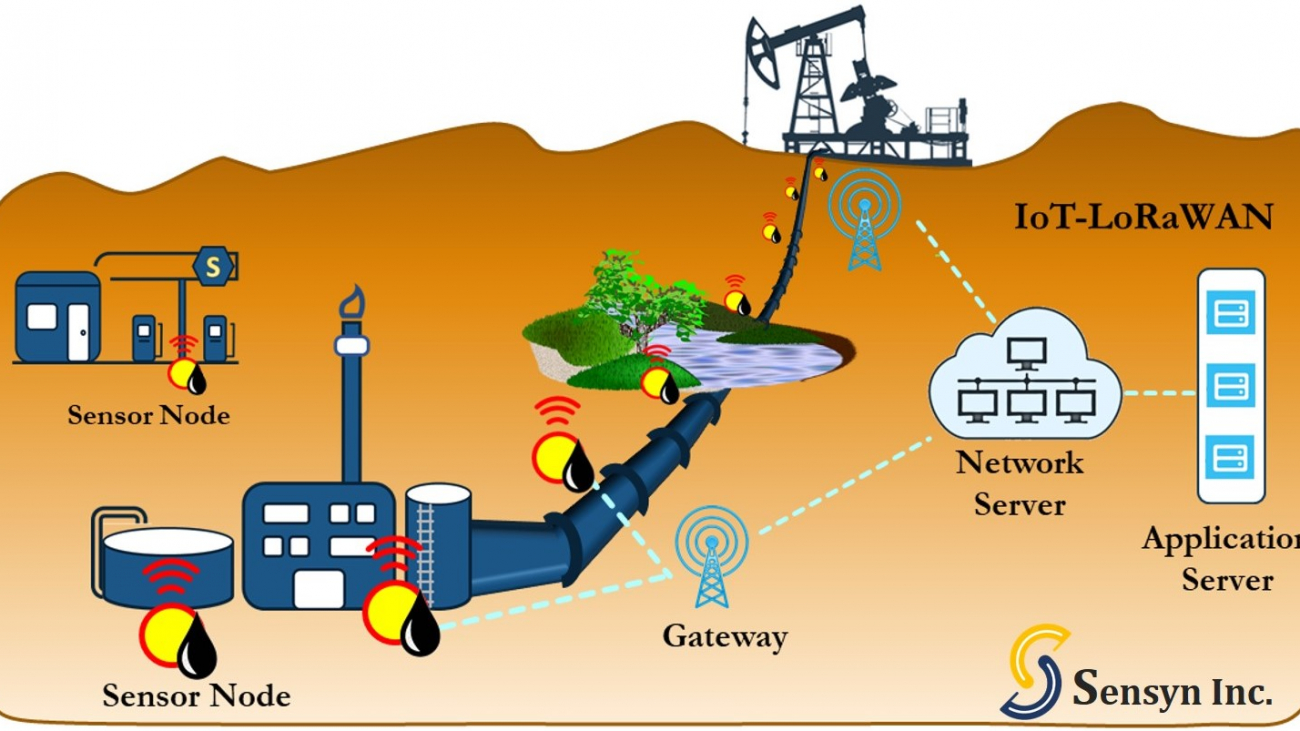

- In-Situ Sensors: In-situ sensors are devices that can detect oil spills in the water. These sensors can be deployed on buoys, floating platforms, or other structures to provide real-time information about the spill. However, in-situ sensors may not be effective in detecting spills in rough sea conditions or areas with high wave heights.

- Mounted Sensors on Sea Vessels: Mounted sensors on sea vessels can also detect oil spills in the water. This technology involves installing sensors on the hull of the vessel to detect changes in the water’s temperature, salinity, or other parameters that may indicate an oil spill. However, this technology may be limited by the availability of vessels equipped with sensors.

While these technologies can be effective in monitoring oil spills, they also have their limitations. For example, satellite imagery and aerial surveys may not be able to detect smaller spills, and in-situ sensors may not work in rough sea conditions or areas with high wave heights. Additionally, these technologies can be expensive to deploy on a large scale.

One potential solution is to use a combination of technologies, such as buoys equipped with sensors and mounted sensors on sea vessels. This approach can provide real-time information about the location and size of the spill, allowing authorities to take prompt action. Moreover, this technology can be deployed in areas where the risk of oil spills is high, allowing for better preparedness in the event of an incident.

To summarize, oil spills in Canada’s water are a significant environmental concern that requires immediate attention. While there are several technologies available for monitoring oil spills, they have their advantages and disadvantages. Combining multiple technologies such as buoys equipped with sensors and mounted sensors on sea vessels could be a convincing approach to prevent oil spills and mitigate their effects. However, more research is needed to overcome the limitations of these technologies and make them more cost-effective for widespread deployment.

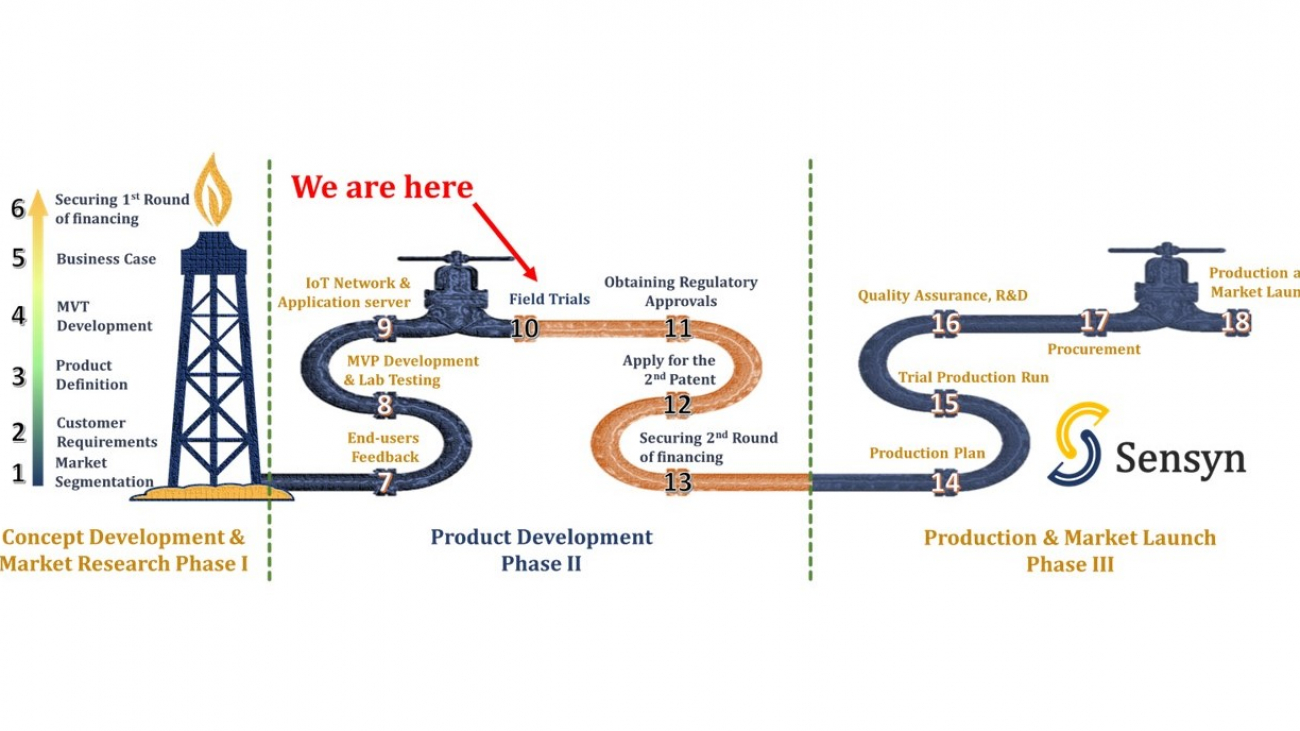

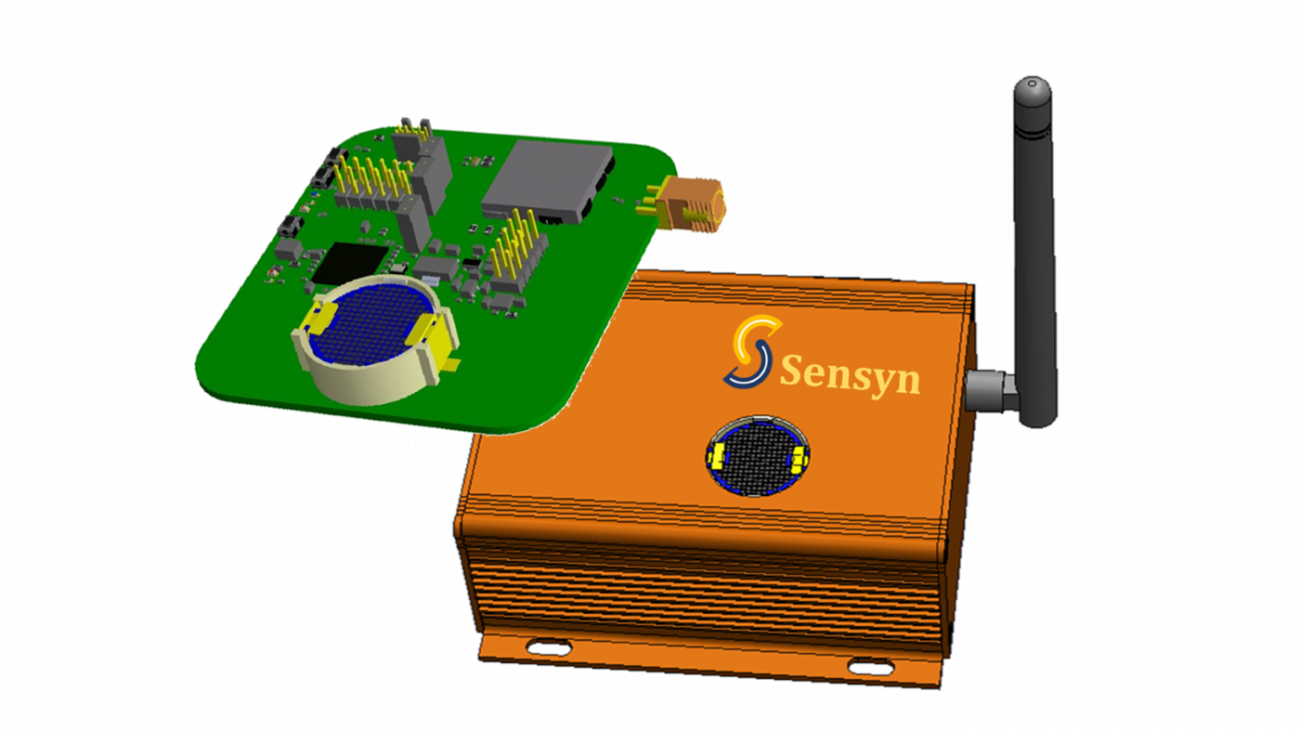

Sensyn, a leading technology company, is actively working to develop the proposed technology of using buoys equipped with sensors and mounted sensors on sea vessels for monitoring oil spills in Canada’s water. The company is investing in research and development to overcome the limitations of existing technologies and make this approach more cost-effective for widespread deployment. Sensyn is committed to providing innovative solutions to protect the marine environment and prevent oil spills, and its work in this area is an important step towards achieving this goal.